New, eco-friendly product: Thermal insulated packaging.

If you’ve been searching for a packaging solution to control the temperature of your goods through transit, you’ve more than likely come across both Woolcool and cotton insulated packaging -

especially if you’re in the pharmaceutical or food and beverage industry.

Both products are great, they’re eco-friendly and offer good temperature management. But we’ve got a brand-new, innovative solution that you need to take a look at. Trust us, you won’t be disappointed.

Drum roll please… 🥁 and the alternative is… PLA Insulation.

As an emerging and innovative packaging material, you may not have come across PLA yet. But not to worry, you’re about to find out why this material has become the talking point in the packaging industry.

How is PLA used in packaging and why?

In the world of packaging, PLA is commonly used as an effective insulator in order to control the temperature of goods during transit. PLA insulation keeps temperature of the internal product around 4 degrees Celsius at an average room temperature of 25-30 degrees Celsius for up to 30 hours.

On top of its insulating properties, PLA doesn’t release any toxic fumes when oxygenated. Therefore, it’s become very popular when packaging pharmaceutical and chemical products. This ensures highly sensitive goods are not contaminated during transit, protecting both handlers and the end user.

Same goes for the food and beverage industry too. Even though studies have revealed PLA does release a small amount of lactic acid, the amount is insignificant to cause harm to humans. For peace of mind, PLA is generally recognised as safe (GRAS) and lactic acid is a common food ingredient anyway. If you’re in the food and beverage industry and looking for a safe, eco-friendly way of packaging you’re your products, consider PLA, you won’t be disappointed.

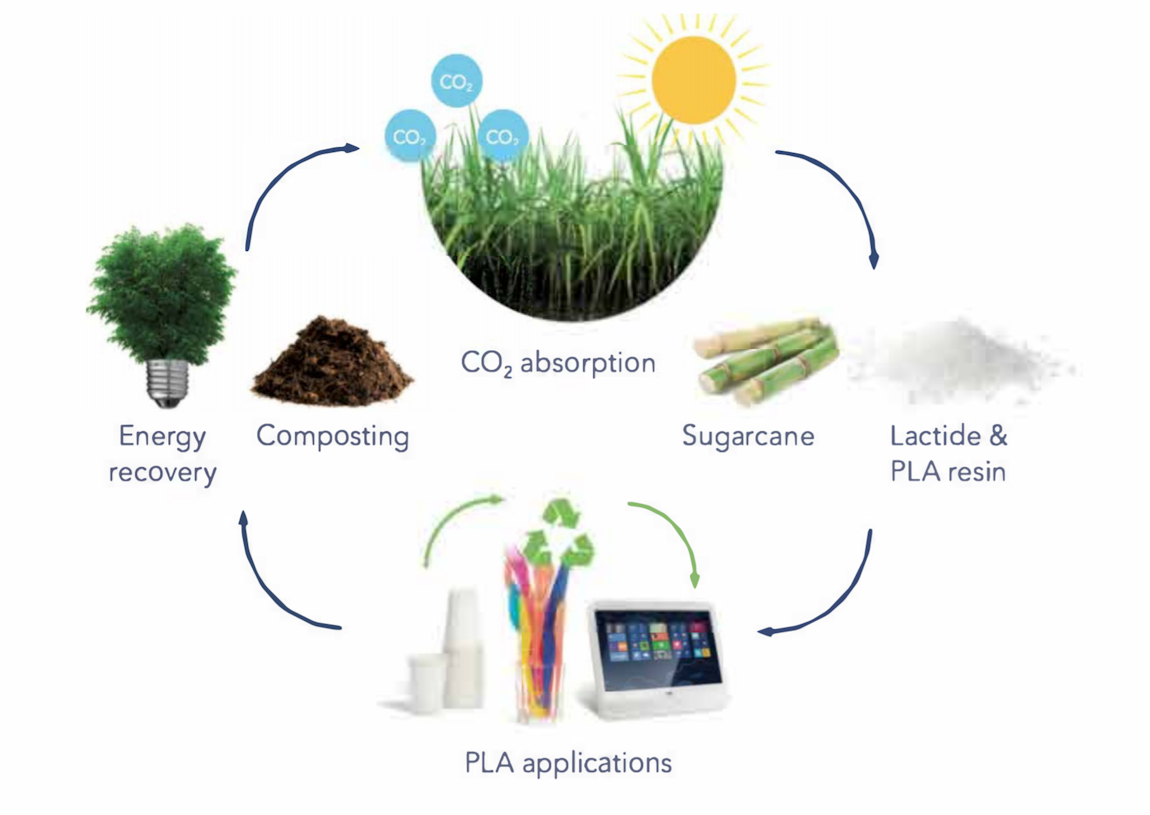

What more? PLA can be fully degraded into carbon dioxide and water through composting, this means no toxins or harmful substances are produced and no pollution is released into the environment.

Carbon reduction with PLA

During the process of PLA production, the emissions generated is considerably less than other polymers alike. The below graph demonstrates Kg of Co2 produced per Kg of each polymer.

PLA packaging product examples

PLA can be utilised in different ways, using different products. From insulation film to insulation pouches and bags, here are some examples we’re fans of at Swiftpak.

PLA insulation felt with film

This product is primarily used to keep food products cool during transit. The flexibility of PLA insulation felt allows for adjustment to fit with most carton sizes and is 100% biodegradable.

PLA self-sealing insulation bag

Again, a great packaging product for the food industry. The strong, uniformed structure of PLA insulation pouches guarantees strong heat preservation, while preventing condensed water from escaping. The outer layer is PLA and PBAT film, with a 100% PLA inner felt that’s needle punched. The PLA self-sealing insulation bag is also 100% biodegradable and suitable for cases where refrigerated and normal temperature products are mixed.

To conclude

PLA packaging is becoming more and more popular by the minute, and there’s no surprise why. If you’d like more information about PLA or would like to find out how PLA packaging could benefit your business, contact Swiftpak today.