The complete guide to strapping machines

Strapping offers an ideal solution for securing shipments before transit or for medium to long-term storage. Whether you need to fix cartons to a pallet, join one parcel to another, or offer additional strength to your delivery, strapping can be used in several ways for a more versatile packaging scheme.

For those looking to incorporate strapping into their operation, or simply want to re-visit their existing strapping solution, it’s important to consider the machine used to apply the strapping and what you’re looking to achieve – strapping machines can’t be overlooked.

If you’d like to find out more about strapping machines, how they work, and what’s best for you, you’ve come to the right place. Here, we explore all you need to know in our complete guide to strapping machines.

What is a strapping machine?

Strapping machines are electrically powered and use strapping to create consistent, secure seals on parcels and packages. They are used to save time, energy and materials over typical packaging processes, and do so without the need of manual strapping tools such as tensioners, cutters or combination tools.

What are the different types of strapping machines?

Depending on your wants and needs as a business, there are two main types of strapping machines to consider – automatic and semi-automatic strapping machines. Let’s take a closer look at each type below.

Automatic strapping machines

Given away in its name, automatic strapping machines are the quickest and simplest to use once setup. With just the push of a button, you’re able to apply strapping to your chosen package in seconds.

Semi-automatic strapping machines

As you may have guessed, semi-automatic strapping machines require a little more involvement from the operator. Although a simple operation, the process takes slightly longer than using a fully automatic strapping machine.

Need help with your strapping?

Our expert team at Swiftpak can help. With over 40 years’ experience in the field, we have the knowledge and experience needed to recommend the best strapping solution for you. If you’d like some advice, or have any strapping related questions, feel free to contact us today.

How do strapping machines work?

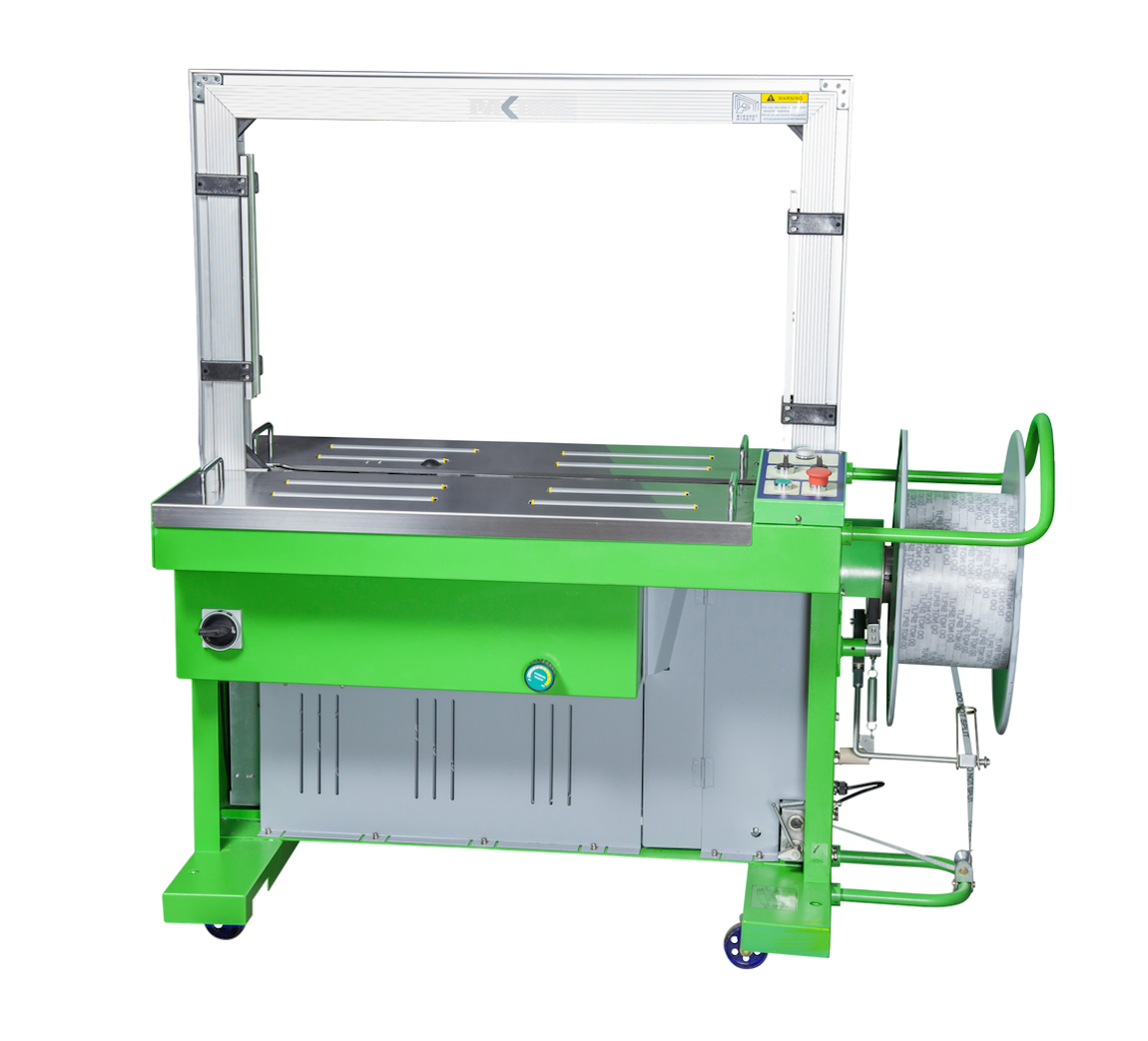

Both automatic and semi-automatic strapping machines work in similar ways. They feature a flat surface to work on, and the strapping is typically fed from the bottom or side of the machine.

In order to begin strapping, you must place in the item in the correct position detailed by the machine. An automatic machine will then do the strapping from a push of a button.

For semi-automatic machines however, you’ll need to feed the strap over the top of the item and into the other side where it’s fed back into the machine (this is what automatic machines do without manual intervention).

Which strapping machine is right for me?

When it comes to choosing the most effective strapping machine for your operation, it all depends on how often it’s used (as well as budget of course). For busy operations with items needing to be strapped regularly, the output rates and ease of use that automatic strapping delivers simply can’t be beaten. For less demanding operations, a semi-automatic strapping solution still offers exceptional efficiency and may be a more cost-effective solution based on usage.

If you’d prefer to speak to an expert though and ensure the optimal strapping solution is in place for your business, contact our team at Swiftpak today, we’re more than happy to advise.

Strapping machines from Swiftpak

At Swiftpak, we stock both automatic and semi-automatic strapping machines from our Paktool range. Built with simplicity of use, reliability and value in mind, the automatic and semi-automatic machines provide our clients with the ultimate strapping solution. If you’d like to learn more about out strapping machines, and how we can help improve the productivity, safety, and cost-effectiveness or your packaging operation, speak to one of our experts at Swiftpak- we’re standing by to answer your queries.